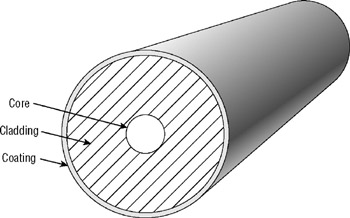

Laser launches that rely on fiber coupling are awesome. There is no need to physically shoot the laser or lasers into a microscope via optics alone. Instead the lasers are delivered into a fiber, and then the fiber can be connected to any point on the microscope. Anyone that has a laser launch is already familiar with this info, what most of us don’t know is how easily you can damage your fiber! First, let’s look at how our fibers are constructed.

Almost all modern laser fibers used in microscopy are of one type. This type is referred to as a single mode, “panda” PM fiber.

Single mode vs. multi mode fibers:

The basic difference here is the core size of the fiber. Multi mode fiber cores are usually 62.5um diameter. Single mode fibers are 10um or smaller. The larger the core diameter, the more propagation patterns (or more accurately Transverse Electromagnetic Mode or TEM patterns) can be sent through the fiber. In a nutshell, the smaller the fiber diameter, the cleaner the output light “shape” will be. Here are some examples of the shapes can can be delivered from a fiber. Obviously we want the one in the upper left (or TEM00 in the image below). So for most applications, single mode fiber makes the most sense. The downside is how small the coupling point is, which makes it difficult to shoot, or “couple”, the laser beam into the fiber.

Panda “PM” Fiber

When using lasers, which are inherently polarized, it’s ideal that we maintain the polarization of the laser beam through the fiber. Fiber types that do this are referred to as Polarization Maintaining, or PM fibers. On order for this to work, stress is applied to the fiber, which causes polarized waves to maintain their state as they travel through the fiber core. There are three common variants of this used, all being named for how they look. Panda, which is named due to the shape of the two large rods vs. the center lighter core, is the oldest and most common, and is what we use in life science. Bow-tie is used mostly for military applications, and elliptical clad is the least commonly used.

Damage and Cleaning

Considering that the above fiber is so tiny (3um) and that this fiber tip can be exposed to particulate matter in the air, it’s likely that when a fiber tip is exposed, a small particle could land on the core of the fiber. Next consider how much light energy is traveling down that core. It’s not uncommon to have 100mW or more power shooting out of a 3um diameter output. This is a massive amount of focused energy. So, when that energy hits that little bit of dust or contamination on the tip of the fiber, it basically cooks on. This can cause back reflection, which is bad for the laser, as well as simply cause a power loss. In order to avoid this we want to keep the fiber tip clean, and if needed polish the fiber to fix any burned on areas.I’ve found two great guides on cleaning a fiber, instead of detailing the work here. Both links are written for those in the telcom world, but the methods and principles apply here. The inspection and cleaning process should happen when:

- You un-cap a fiber tip.

- You remove a fiber from a mounting point on the scope.

- You notice a decrease in transmission from your laser launch.

In order to clean a fiber you’ll need a few special tools and supplies. I’ve used the kit supplied by Realm Communications. If you don’t clean a fiber, here are some examples of tip contamination that will inevitably end up giving you trouble.

So – Learn how to clean a fiber via the links below, or give your local rep a call so he or she can do this for you!!!

Fiber Inspection and Cleaning Instructions # 1

Fiber Inspection and Cleaning Instructions # 2

-Austin

Comments

2 responses to “Fiber inspection and cleaning – why it matters!”

[…] use lasers primarily for single mode fiber coupling. I explained how this is done in my post on fiber types used in microscopy. One of the requirements for fiber coupling is that the beam quality emitting from the laser must […]

Construction inspector London

Nice Blog! We have read a few of the interesting content on your website now, and we really like your style. Thanks a million and please keep it up the effective work.